Eyewear is more of a work of art than an industrial product.

「Eyewear is more of a work of art than an industrial product」

This is the management philosophy that our founder, Isamu Niwa, maintained from the start of Ena Optical. We produce eyeglass frames with the quality and design that consumers want by focusing on the production processes and materials to realize the comfort that will satisfy all wearers of eyewear.

「Passion for comfort」

We value the comfort we can provide to eyeglass wearers, the end users of our products, above all else. We provide unique comfort and satisfaction the moment the wearer puts on one of our eyeglass frames. One customer described our frames as feeling “soft as a baby’s skin.” Customers remember this feeling, and all consumers that we asked said that they could identify an Ena Optical frame in an instant. Our aim is to satisfy customers by producing the best eyewear based on our passion for comfort.

Commitment to in-house production

Since our founding in 1947, Ena Optical has employed a full in-house production approach by handling all processes from cutting materials through completing and shipping eyeglass frames in our plant in Nakatsugawa, Gifu Prefecture, Japan. We strive to improve our technologies and quality to meet the exacting demands of global standards. These efforts are rooted in the confidence that we are the only manufacturer capable of producing eyeglass frames at the quality level that we demand of our products. Only the employees who build our frames fully understand what makes them so comfortable the moment the wearer puts them on. Our final in-house inspection process ensures that there is nothing unusual about the feel of each frame before shipping to the customer. We also prevent defects in the production process by quickly identifying and correcting any deviations of as little as one millimeter.

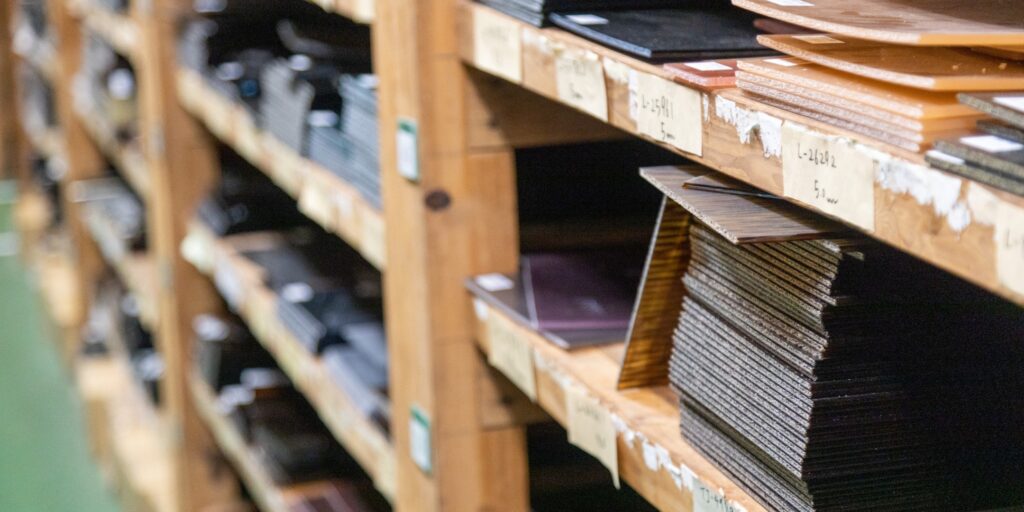

Commitment to materials

Acetate resin is the most popular eyeglass frame material today. Ena Optical was an industry pioneer in successfully developing acetate-resin eyeglass frames in 1957 by establishing a structure for mass production and building the foundation for advancement into international markets. Since then, we have received OEM production orders from numerous eyeglass brands throughout Japan and around the world. Today, we produce about 200,000 frames per year, and about 90% are supplied to international brands on an OEM basis.

Eyeglass frames are made of acetate resin while curving the resin sheet. Different colors can be produced in deep hues. Our aim is to continue to provide eyeglass frames that satisfy consumers as we build further on the proprietary technologies that we inherited since our founding.